If you’ve ever dived into the world of plumbing, you might have stumbled upon the term MIP. But what does it actually stand for? Understanding plumbing fittings can feel like learning a new language, and MIP is one of those crucial terms that every homeowner should be familiar with. Whether you’re tackling a DIY project or want to converse fluently with your plumber, understanding the ins and outs of MIP fittings will empower you to manage your house plumbing system effectively. Let’s unravel this essential part of plumbing together!

Understanding the Different Types of MIP Fittings

MIP fittings come in various forms, each serving a specific purpose. The most common types include male threads and female threads. Male Iron Pipe (MIP) fittings feature external threads that enable them to screw into female counterparts, thereby creating a secure connection.

There are also elbows and tees among MIP options. Elbows help change the direction of pipe runs, while tees connect three pipes at once. These shapes are essential for navigating plumbing layouts effectively.

Understanding these types will enhance your ability to tackle projects confidently. Each fitting type has its own strengths and ideal applications, making it easier to select the one that best suits your needs.

Common Uses for MIP Fittings in Plumbing

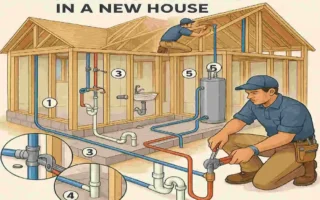

MIP fittings, also known as Male Iron Pipe fittings, are versatile components in plumbing design systems. They’re primarily used to connect pipes and fixtures securely.

One common application is in residential water supply systems. MIP fittings help link threaded pipes to valves or faucets, ensuring a tight seal that prevents leaks.

Another frequent use is in gas lines. These fittings provide reliable connections for natural gas appliances, such as stoves and dryers. Their durability makes them ideal for high-pressure environments.

MIP fittings also play an essential role in heating systems. They connect various elements of radiant heat installations, enhancing efficiency throughout the home.

These adaptable connectors can even be found in irrigation systems where they join hoses and sprinkler heads seamlessly. This flexibility makes MIP a go-to choice for many plumbing needs.

Benefits and Drawbacks of Using MIP Fittings

MIP fittings, or Male Iron Pipe fittings, offer several benefits that make them popular among plumbers. They provide robust connections and are perfect for high-pressure applications. Their durability ensures longevity, reducing the frequency of replacements.

On the downside, MIP fittings can be prone to corrosion over time if not properly maintained. This issue is particularly prevalent in humid environments or areas with poor water quality.

Installation can also pose challenges; it requires precise threading to avoid leaks and ensure a secure fit. For DIY enthusiasts, this requires additional skills.

Despite these drawbacks, many prefer MIP fittings due to their strength and reliability in plumbing systems, making them a staple choice for various installations.

Tips for Choosing and Installing MIP Fittings

Choosing the right MIP fittings starts with understanding your project requirements. Consider the size and type of piping you’re working with. MIP fittings come in various configurations, so take your time with this step house design.

Look for high-quality materials, such as brass or stainless steel. These options are durable and resistant to corrosion, ensuring a longer lifespan for your plumbing system.

When installing, ensure that all threads are clean and free from debris. This will help achieve a secure seal and prevent leaks down the line. Applying Teflon tape can enhance sealing on threaded connections.

Use a wrench to tighten fittings snugly, but avoid over-tightening, as this can damage the threads or crack the fitting itself.

Double-check alignment before entirely securing everything in place. Misaligned fittings can create stress points that may lead to future issues.

How to Properly Maintain and Repair MIP Fittings

Maintaining MIP fittings is crucial for ensuring a leak-free plumbing system. Regular inspections are your first line of defense. Look for signs of corrosion or wear and tear.

If you notice any issues, address them promptly. Tighten loose connections gently; overtightening can cause damage.

For repairs, turn off the water supply before starting work on any fitting. Use appropriate tools to avoid stripping threads during removal and installation.

When replacing old fittings, ensure you clean threaded areas thoroughly to create a proper seal with new tape or compounds. This step prevents future leaks.