Estimating basement costs for manufactured homes involves considering several key factors, including the size of the basement, soil and site conditions, foundation type, and local labor and material costs. Since manufactured homes often require special foundation considerations, such as reinforced or crawl space foundations, costs can vary widely. A rough estimate typically starts with calculating the square footage of the basement area to be constructed or finished, then multiplying by a price per square foot that reflects regional pricing and the complexity of installation.

What is a Manufactured Home?

Manufactured homes, often referred to as mobile homes, are factory-built residences. They come in various styles and sizes but share one key characteristic: they are constructed off-site. Once built, these homes are transported to their permanent locations.

These houses provide an affordable housing option for many families. They can be placed on private land or within designated communities. Manufactured homes offer flexibility since they can be customized with different floor plans and finishes.

Typically built according to federal standards set by HUD (Department of Housing and Urban Development), manufactured homes ensure safety and quality. Unlike traditional site-built homes, which take months to complete, manufactured options can be ready in a fraction of the time.

Today’s designs range from compact single-section models to expansive multi-section layouts that rival conventional houses in comfort and style. Their appeal continues to grow among those seeking budget-friendly living without sacrificing quality or aesthetics.

Advantages of Building a Basement for a Manufactured Home

Building a basement for a manufactured home offers numerous advantages. It significantly increases living space. This additional area can be transformed into anything from a cozy den to extra bedrooms or even an office.

You may also read (top 4 features to consider when building your dream home).

Moreover, basements provide excellent storage solutions. With limited square footage in many manufactured homes, having that extra room beneath the floor helps keep clutter at bay.

Basements also enhance the property’s value. A well-designed and functional basement can attract potential buyers if you decide to sell your home later on.

From an energy efficiency perspective, basements often help maintain stable indoor temperatures. They can act as natural insulators against extreme weather conditions.

They offer unique design opportunities. Homeowners have the freedom to create personalized spaces tailored to their lifestyle needs while adding character to their manufactured home.

Factors to Consider When Budgeting for a Basement in a Manufactured Home

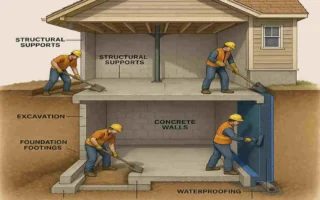

When budgeting for a basement in a manufactured home, several critical factors come into play. First, consider the soil type on your property. Certain soils require extra excavation work and support structures, which can increase costs.

Next, think about local building codes. These regulations can dictate specific requirements for basements that may add to your budget. Always check with local authorities before starting any project.

Another critical factor is drainage systems. Proper drainage is essential to prevent water damage and mold growth. Installing effective drainage solutions may raise initial expenses, but it protects your investment long-term.

Evaluate potential design features you want in your basement—such as windows or additional rooms—as these choices will affect the overall cost significantly. Each decision impacts both functionality and price, so weigh them carefully as you plan your budget.

Average Costs for Different Types of Basements

When considering basement costs for manufactured homes, it’s essential to understand the different types available.

A crawl space is often the most economical option, typically ranging from $5,000 to $15,000. This choice is excellent for those wanting minimal excavation and straightforward access.

On the other hand, a full basement usually comes with a higher price tag. Expect costs between $20,000 and $50,000, depending on size and complexity. Full basements offer more living space and can significantly increase your home’s value.

For those looking for something in between, consider a partial basement or walk-out design. Prices generally range from $15,000 to $30,000. This option provides easy outdoor access while still offering additional interior space.

Each type of basement serves distinct needs but varies widely in cost based on location and local building codes. Being aware of these options will help you make informed decisions as you plan your project.

Additional Costs to Keep in Mind

When budgeting for a basement in a manufactured home, several additional costs can sneak up on you. Permits and inspections are often overlooked but can add significant expenses to your project. Check local regulations to ensure compliance.

Don’t forget about waterproofing and drainage systems. These features are crucial for preventing future water damage and mold growth, especially if you’re building below ground level.

Utility connections also play a vital role in cost estimation. If you’re adding plumbing or electrical systems, those installations may require professional help, leading to higher labor charges.

Consider the landscaping changes as well. Excavation work might disturb your yard, necessitating further soil work or planting new grass and plants afterward.

Consider interior finishing options, such as flooring and drywall, that will enhance your basement’s look, while also significantly impacting your budget.

Tips for Saving Money on Basement Costs

One effective way to save on basement costs is to plan ahead. Start by thoroughly researching local building codes and requirements. This ensures you won’t face unexpected expenses due to permits or violations later.

Consider working with a contractor who has experience in manufactured homes. Their familiarity can lead to efficiencies that save both time and money.

Utilizing the right materials can also make a significant difference. Opt for cost-effective yet durable options, like engineered wood instead of solid timber, where appropriate.

Another tip is timing your project during off-peak seasons when labor costs may be lower. You might find better deals on materials as well.

Take advantage of DIY opportunities for non-structural tasks such as painting or insulation installation. Every little bit helps when it comes to reducing overall expenses while still achieving the desired outcome for your basement.

You may also read (easy hvac utility access solutions for new construction).