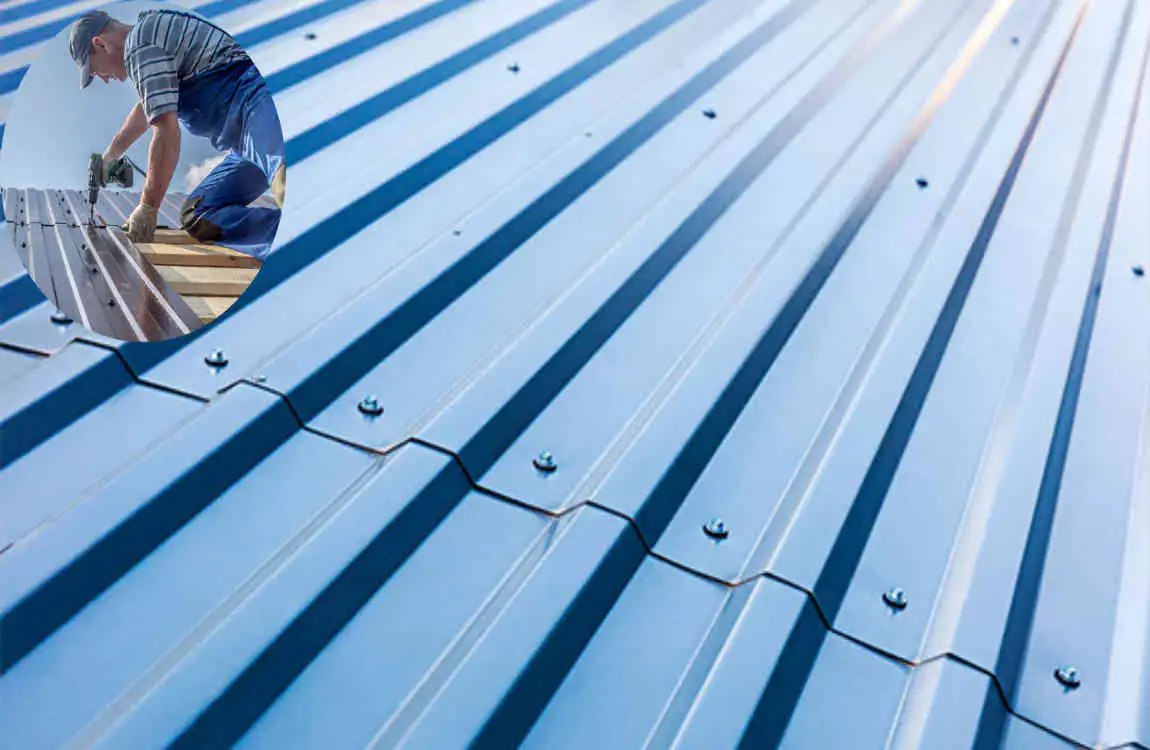

When it comes to metal roofing, many homeowners and builders often overlook a crucial detail: the screws that hold everything together. Yet, these small fasteners play a massive role in the roof’s durability, weather resistance, and overall performance. Choosing the right screws isn’t just about picking any fastener — it’s about selecting those specially designed to handle the unique demands of metal roofing.

Understanding Metal Roofing and Its Fastening Needs

Metal roofing has gained popularity due to its strength, longevity, and sleek appearance. However, not all roofs are the same, and neither are the screws that hold them in place.

Common Types of Metal Roofing Panels

Metal roofs come in various materials, each with its own characteristics:

- Steel: Strong and cost-effective, often coated to resist rust.

- Aluminum: Lightweight and corrosion-resistant, ideal for coastal areas.

- Copper: Expensive but visually stunning and highly durable.

- Zinc and Tin: Less common but used for specialty roofing projects.

Each of these metals requires screws that can match their properties to prevent issues such as corrosion or poor grip.

Why Metal Roofing Needs Specific Screws

Metal roofing isn’t like shingles or tiles. It requires fasteners with:

- Strong holding power: To keep panels firmly in place against wind and weather.

- Corrosion resistance: Screws are exposed to rain, snow, and moisture, so rust-roof design materials are essential.

- Effective sealing: To prevent water leaks where screws penetrate the metal surface.

Screws vs. Nails for Metal Roofing

Unlike traditional roofing nails, screws provide a much tighter and more secure hold. Nails tend to loosen over time, especially in the presence of wind or thermal expansion of metal panels. Screws, on the other hand, have threads that grip the metal and the underlying structure, thereby maintaining the roof’s integrity.

Role of Washers and Sealants

Most metal roofing screws come with rubber or neoprene washers that seal the hole, preventing water from entering. These washers work like tiny gaskets, compressing under the screw head to form a waterproof barrier. Sometimes, additional sealants are applied to enhance leak protection.

Types of Screws for Metal Roofing

Choosing the correct type of screw is critical. Let’s break down the main kinds used in metal roofing and when to use each.

Self-Drilling Screws

These are the most popular screws for metal roofing. Why? Because they can drill their own hole as they’re driven in, which speeds up installation.

- Ideal for attaching metal panels to wood or metal framing.

- They have a pointed, drill-like tip that eliminates the need for pre-drilling.

- Suitable for use with thinner metal panels.

Self-Tapping Screws

Unlike self-drilling, self-tapping screws require a pilot hole. They cut threads into the metal once the insert is in place.

- Used when working with thicker metal or more rigid substrates.

- Provides strong fastening, but requires a bit more preparation work.

- Often chosen for retrofit or repair jobs.

Hex-Head Screws

These screws feature a hexagonal head, making them easy to drive with a standard wrench or hex driver bit.

- The hex head offers excellent torque application.

- Preferred for heavy-duty applications where a firm grip is necessary.

- Often paired with sealing washers to prevent leaks.

Pan-Head Screws

Pan-head screws have a rounded, flat top that sits above the surface.

- Suitable for applications where appearance matters.

- Provide a smooth finish and good holding power.

- Sometimes used for attaching trim or flashing on metal roofs.

Screws with Integrated Sealing Washers

Many metal roofing screws come with a built-in rubber or neoprene washer bonded to the underside of the head.

- These washers compress to seal against water penetration.

- Reduce the risk of leaks around screw holes.

- Essential for weatherproofing and extending roof life.

Compatible Screw Threads and Pitch

The thread design matters. Screws with coarse threads grip wood framing more effectively, while fine threads are better suited for metal-to-metal fastening. The pitch (distance between threads) affects how easily the screw drives in and how strong the hold is.

Materials and Coatings for Metal Roofing Screws

Because roofing screws are constantly exposed to the elements, their material and finish are crucial to their durability.

Importance of Corrosion Resistance

Rust can quickly ruin a metal roof’s performance. Rusty screws lose grip, create leaks, and can stain roofing panels. Therefore, corrosion-resistant screws are essential.

Common Screw Materials

- Stainless Steel: Highly rust-resistant, excellent for coastal or humid areas. More expensive but very durable.

- Galvanized Steel: Steel coated with zinc, offering good corrosion resistance at a lower price point.

- Aluminum: Lightweight and resistant to rust, but softer and less intense.

- Zinc-Coated: Provides decent protection but can wear off over time.

Coating Types Explained

- Hot-Dip Galvanized: A thick layer of zinc is melted onto the screw, providing excellent long-term protection.

- Electro-Galvanized: Thinner zinc coating applied electrically. Less durable than hot-dip.

- Paint or Powder Coated: Adds color and extra protection, but can chip under stress.

Matching Materials to Roofing Types and Environments

- For steel roofs, galvanized or stainless steel screws are best.

- Aluminum roofs pair well with aluminum screws to avoid galvanic corrosion.

- Copper roofs require screws compatible with copper or stainless steel.

Benefits of Coated Screws

Coated screws prevent rust, reduce staining, and help your roof features maintain its appearance and function for years. They also protect against moisture and UV damage.

Choosing the Right Screw Size and Length

Selecting the correct screw size is just as important as choosing the type and material of the screw.

Determining Screw Length

The screw must be long enough to:

- Pass through the metal panel.

- Secure firmly into the underlying structure (wood or metal framing).

A general rule: screw length = panel thickness + at least ¾ inch into the substrate. Too short, and it won’t stay in place. Too long, and it may damage the underlying materials or poke through.

Recommended Diameter and Head Size

- A diameter of around ¼ inch (8 gauge) is standard for metal roofing screws.

- The head size should be broad enough to hold the washer and distribute pressure evenly without tearing the panel.

Standard Sizes in Residential and Commercial Use

Screw Diameter Typical Lengths Application

#10 (5mm) 1 inch to 2 inches Light residential panels

#12 (6mm) 1.5 inches to 3 inches Heavy-duty industrial panels

1/4 inch , 1.5 inches to 3 inches Commercial roofing

Avoiding Common Mistakes

Using screws that are too short results in weak fastening. Too-long screws can damage insulation or decking. Oversized screws may split the framing wood or strip the threads of the screws, causing damage.

Installation Considerations: How to Use Screws for Metal Roofing

Proper installation ensures your screws perform well and your roof stays secure.

Pre-Drilling and Self-Drilling Advantages

- Self-drilling screws reduce prep time because no pilot holes are needed.

- For thicker metals, pre-drilling can prevent panel warping or screw breakage.

Screw Placement and Spacing

- Screws should be spaced about 12 to 24 inches apart on metal panels.

- Along edges and overlaps, closer spacing improves weather resistance.

- Follow manufacturer guidelines for exact spacing.

Torque Settings and Tools

- Use a drill with adjustable torque settings to avoid over-driving screws.

- Over-tightening can strip threads or crush washers, causing leaks.

- Under-tightening leads to loose screws and poor holding power.

Use of Sealing Washers

- Always use screws with sealing washers for metal house roofs.

- Ensure the washer compresses evenly under the screw head.

- Replace damaged washers during maintenance.

Screw Alignment Tips

- Align screws in straight rows for a neat appearance.

- Consistent spacing improves both function and aesthetics.

Common Challenges and How to Avoid Them

Even with the right screws, problems can arise.

Issues from Incorrect Screws or Installation

- Leaks: Caused by missing or damaged washers or over-driven screws.

- Rust: Using incompatible materials or poor coatings.

- Loosening: Thermal expansion and contraction can cause screws to loosen if not tightened properly.

Troubleshooting Loose or Stripped Screws

- Replace loose screws immediately.

- For stripped holes, use a larger diameter screw or repair the hole with a metal patch.

Safe Screw Replacement

- Remove damaged screws carefully to avoid panel damage.

- Use matching screws and washers for replacements.

Preventive Maintenance Tips

- Inspect screws annually.

- Tighten any loose fasteners.

- Replace rusty or worn screws promptly.

Where to Buy Quality Screws for Metal Roofing

Finding reliable suppliers is crucial to obtaining high-quality fasteners.