Building a new home is an exciting journey, but it can also be overwhelming. One of the most crucial aspects of any construction project is ensuring you have the right amount of materials. When it comes to building a house, lumber is one of the most critical components. Getting your lumber calculations right can make all the difference in avoiding waste and costly overruns.

We’ll explore the basics of lumber, break down the components of a house that require it, and walk you through a step-by-step process for estimating your needs. By the end, you’ll have a solid understanding of how much lumber is needed to build a house and the tools to make accurate house calculations for your own project.

Understanding Lumber Basics

Before we jump into the nitty-gritty of calculations, let’s make sure we’re on the same page about what lumber is and why it matters.

What is Lumber?

Lumber is simply wood that has been processed into beams, planks, or boards. In home construction, you’ll encounter several types of lumber:

- Dimensional lumber: This is the standard, rectangular-shaped wood used for framing and structural purposes.

- Engineered wood: Made from wood fibers, veneers, or strands, engineered wood offers strength and stability.

- Treated lumber: This type of lumber is infused with chemicals to resist rot, insects, and weathering, making it ideal for outdoor use.

Key Lumber Measurements

When working with lumber, it’s essential to understand a few key measurements:

- Board feet: This is the standard unit of measurement for lumber volume, calculated as thickness (in inches) x width (in inches) x length (in feet) divided by 12.

- Linear feet: This measures the length of lumber in a straight line.

- Nominal vs. actual dimensions: Lumber is often sold based on nominal dimensions (e.g., 2×4), but the actual size is slightly smaller due to the milling process.

Standard Lumber Sizes for Home Framing

In most home construction projects, you’ll encounter a few standard lumber sizes:

- 2×4: Used for wall studs, plates, and smaller framing components

- 2×6: Common for floor joists and larger framing elements

- 2×8 and 2×10: Often used for roof rafters and beams

Why Choosing the Right Lumber Matters

Selecting the appropriate type and size of lumber is crucial for several reasons:

- Structural integrity: The right lumber ensures your home can withstand loads and forces.

- Cost efficiency: Using the correct lumber minimizes waste and keeps your budget in check.

- Durability: Choosing lumber suited for its intended use extends the life of your home.

Now that we’ve covered the basics, let’s explore how lumber is used in different parts of a house.

The Components of a House That Require Lumber

A house is made up of many parts, and lumber plays a vital role in constructing most of them. Let’s break it down:

Framing Lumber

Framing lumber is the backbone of your home’s structure. It includes:

- Walls: Studs, plates, and headers form the vertical support of your walls.

- Floors: Joists and beams create the framework for your floors.

- Roof: Rafters, trusses, and ridge boards shape your roof’s structure.

Sheathing and Subfloor Materials

Once the framing is in place, you’ll need lumber for:

- Sheathing: This covers the exterior walls and roof, providing a base for siding and roofing materials.

- Subfloor: Plywood or oriented strand board (OSB) forms the base layer of your floors.

Interior Structures

Inside your home, lumber is used for:

You may also read (building a house).

- Stairs: Stringers, treads, and risers make up your staircases.

- Partitions: Non-load-bearing walls that divide your living spaces.

- Built-ins: Shelving, cabinets, and other custom features often incorporate lumber.

Exterior Features

Don’t forget about the outside of your home:

- Decks and porches: Lumber forms the structure and decking for these outdoor spaces.

- Fascia and trim: These finishing touches add style and protection to your home’s exterior.

Now that we’ve covered the various components that require lumber, let’s dive into the process of calculating your needs.

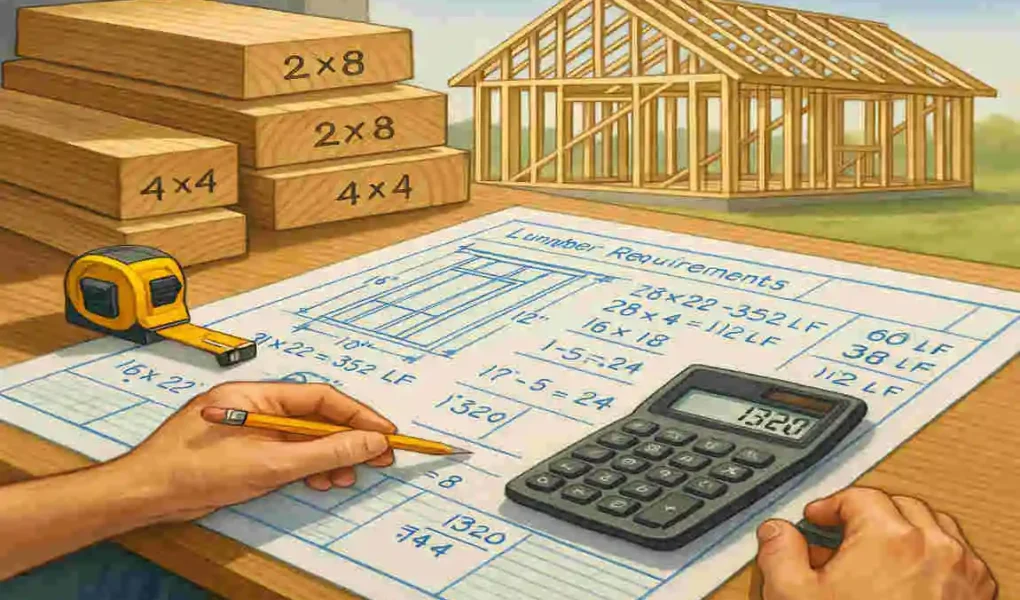

How to Calculate Lumber Needs for Your Home Project

Calculating the right amount of lumber for your new home project involves a series of steps. Let’s walk through them together:

Understand Your House Design and Dimensions

Before you can start calculating, you need a clear understanding of your home’s design and dimensions. Study your blueprints or plans to gather information about:

- The overall size and layout of your home

- The number of stories and the roof style

- Any custom features or unique elements

Calculate Lumber for the Foundation Frame and Floor Joists

Start with the base of your home:

- Foundation frame: Calculate the perimeter of your foundation and determine the size and spacing of the sill plates and rim joists.

- Floor joists: Based on your home’s dimensions and the desired joist spacing, calculate the number and length of joists needed for each floor.

Estimating Lumber for Wall Framing

Walls are a significant component of your lumber needs:

- Studs: Calculate the number of studs needed based on the wall length and desired stud spacing (typically 16 or 24 inches on center).

- Plates: Determine the length of the top and bottom plates for each wall.

- Headers: Estimate the size and quantity of headers needed for doors, windows, and other openings.

Roof Framing Lumber Calculation

The roof is another critical area:

- Rafters or trusses: Depending on your roof design, calculate the number and length of rafters or trusses needed.

- Ridge board: Determine the length of the ridge board that runs along the peak of your roof.

- Collar ties and purlins: If required, estimate the number and length of these additional framing components.

Additional Lumber Considerations

Don’t forget about these essential elements:

- Sheathing: Calculate the area of exterior walls and roof to determine the amount of sheathing needed.

- Blocking and bracing: Estimate the amount of lumber required for additional support and stability throughout your home.

Applying Waste Factor and Contingency Buffer

Finally, account for waste and unexpected needs:

- Waste factor: Add a percentage (typically 5-10%) to your calculations to account for cutting waste and mistakes.

- Contingency buffer: Consider adding an extra 5-10% to your total to cover any unforeseen changes or additions during construction.

Now that you have a solid understanding of the calculation process, let’s explore the tools and methods available to help you estimate your lumber needs.

Tools and Methods for Lumber Estimation

Calculating lumber requirements can be done in various ways, depending on your comfort level with numbers and technology. Here are some options:

Manual Calculation Methods

If you prefer a hands-on approach, you can use formulas and measurement strategies to calculate your lumber needs. This method requires a solid understanding of mathematics and meticulous attention to detail.

Lumber Calculators and Online Tools

For a quicker and more user-friendly approach, consider using lumber calculators and online tools. These resources often have pre-built formulas and can save you time and effort.

Blueprint Reading for Lumber Quantities

If you have access to your home’s blueprints, you can use them to estimate lumber needs. This method involves carefully reading and interpreting the plans to identify the required materials.

Interpreting Lumber Takeoffs from Construction Plans

For more complex projects, you may need to perform a lumber takeoff. This involves creating a detailed list of all the lumber required, based on the construction plans. Professional estimators and contractors often use this method.

Now that we’ve covered the tools and methods, let’s look at some practical examples of lumber calculations for different home sizes.

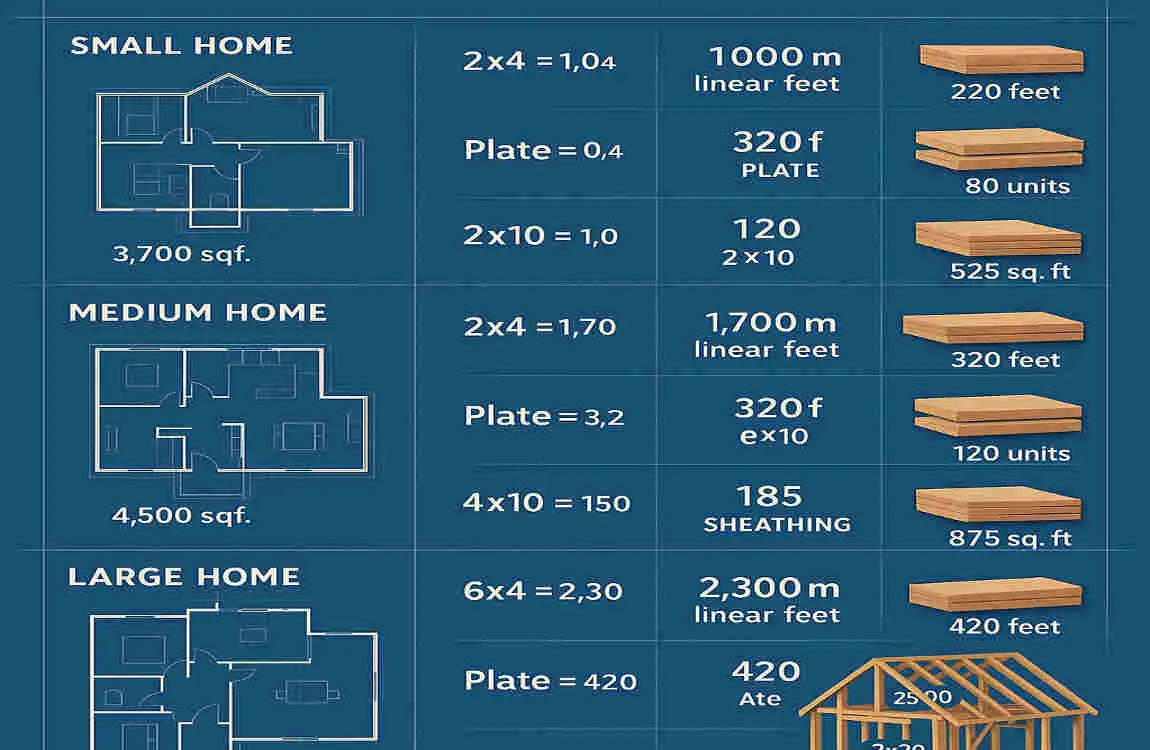

Practical Examples: Lumber Calculation for Typical Home Sizes

To help you better understand how lumber calculations work in real-world scenarios, let’s walk through some examples for different home sizes.

Calculating Lumber for a Small 1,200 sq ft House

Let’s start with a small, single-story home of 1,200 square feet. Here’s a step-by-step breakdown of the lumber calculation:

- Foundation and floor framing:

- Perimeter: 120 linear feet (assuming a 30×40 foot rectangle)

- Sill plates: 120 linear feet of 2×6 lumber

- Rim joists: 120 linear feet of 2×10 lumber

- Floor joists: 16 joists at 16 inches on center, each 30 feet long (2×10 lumber)

- Wall framing:

- Exterior walls: 4 walls at 30 feet long, two walls at 40 feet long

- Studs: 120 studs (2×4 lumber) at 16 inches on center

- Plates: 240 linear feet of 2×4 lumber (top and bottom plates)

- Headers: 6 headers (2×6 lumber) for doors and windows

- Roof framing:

- Rafters: 16 rafters (2×8 lumber) at 24 inches on center, each 18 feet long

- Ridge board: 40 feet of 2×8 lumber

- Sheathing and subfloor:

- Exterior sheathing: 1,200 square feet of 1/2-inch plywood

- Subfloor: 1,200 square feet of 3/4-inch plywood

- Additional lumber:

- Blocking and bracing: 200 linear feet of 2×4 lumber

- Waste factor and contingency buffer:

- Add 10% waste factor and 5% contingency buffer to the total lumber needs

Using these calculations, you can estimate the total lumber required for a small 1,200 sq ft house.

Estimating Lumber for a Mid-Sized 2,500 sq ft Home

Now, let’s move on to a mid-sized, two-story home of 2,500 square feet. The process is similar, but the quantities will be larger:

- Foundation and floor framing:

- Perimeter: 200 linear feet (assuming a 50×50 foot square)

- Sill plates: 200 linear feet of 2×6 lumber

- Rim joists: 200 linear feet of 2×10 lumber

- Floor joists: 32 joists at 16 inches on center, each 50 feet long (2×10 lumber) for each floor

- Wall framing:

- Exterior walls: 4 walls at 50 feet long

- Studs: 240 studs (2×4 lumber) at 16 inches on center

- Plates: 400 linear feet of 2×4 lumber (top and bottom plates) for each floor

- Headers: 12 headers (2×6 lumber) for doors and windows on each floor

- Roof framing:

- Rafters: 24 rafters (2×8 lumber) at 24 inches on center, each 25 feet long

- Ridge board: 50 feet of 2×8 lumber

- Sheathing and subfloor:

- Exterior sheathing: 2,500 square feet of 1/2-inch plywood

- Subfloor: 2,500 square feet of 3/4-inch plywood for each floor

- Additional lumber:

- Blocking and bracing: 400 linear feet of 2×4 lumber

- Waste factor and contingency buffer:

- Add 10% waste factor and 5% contingency buffer to the total lumber needs

By following these steps, you can estimate the lumber required for a mid-sized 2,500 sq ft home.

Lumber Needs for a Larger 4,000 sq ft Custom Home.

For a larger, custom home of 4,000 square feet, the calculations will be more complex due to the unique design elements and features. However, the process remains the same:

- Foundation and floor framing:

- Perimeter: 280 linear feet (assuming an irregular shape)

- Sill plates: 280 linear feet of 2×6 lumber

- Rim joists: 280 linear feet of 2×10 lumber

- Floor joists: 48 joists at 16 inches on center, each varying in length (2×10 lumber) for each floor

- Wall framing:

- Exterior walls: Varying lengths based on the custom design

- Studs: 360 studs (2×4 lumber) at 16 inches on center

- Plates: 560 linear feet of 2×4 lumber (top and bottom plates) for each floor

- Headers: 18 headers (2×6 lumber) for doors and windows on each floor

- Roof framing:

- Rafters: 32 rafters (2×8 lumber) at 24 inches on center, each varying in length

- Ridge board: 80 feet of 2×8 lumber

- Sheathing and subfloor:

- Exterior sheathing: 4,000 square feet of 1/2-inch plywood

- Subfloor: 4,000 square feet of 3/4-inch plywood for each floor

- Additional lumber:

- Blocking and bracing: 600 linear feet of 2×4 lumber

- Waste factor and contingency buffer:

- Add 10% waste factor and 5% contingency buffer to the total lumber needs

Keep in mind that these are just examples, and your specific lumber needs will depend on your home’s unique design and features.

How Building Style/Layout Affects Lumber Quantity

The style and layout of your home can significantly impact the amount of lumber required. Here are a few factors to consider:

- Single-story vs. multi-story: Multi-story homes require more lumber for additional floors and staircases.

- Roof style: Complex roof designs with multiple peaks and valleys will need more lumber than simple gable or hip roofs.

- Custom features: Built-ins, decks, and other custom elements will increase your lumber needs.

- Open floor plans: Homes with fewer interior walls may require less lumber for framing.

When calculating your lumber needs, be sure to take these factors into account to ensure an accurate estimate.

Now that we’ve covered practical examples, let’s explore some of the factors that can affect your lumber requirements.

Factors That Affect Lumber Requirements

Several factors can influence the amount of lumber needed for your new home project. Let’s take a closer look at some of the most important ones:

Local Building Codes and Regulations

Building codes and regulations vary by location and can impact your lumber choices and quantities. Some key considerations include:

- Minimum lumber sizes: Certain areas may require larger dimensional lumber for framing.

- Spacing requirements: Local codes may dictate the maximum allowable spacing for studs, joists, and rafters.

- Fire ratings: In some regions, you may need to use fire-resistant lumber or additional fire-blocking materials.

Always consult your local building department to ensure your lumber calculations comply with the relevant codes and regulations.

Climate and Environmental Factors

The climate and environment where you’re building can also affect your lumber needs:

- Moisture levels: High-humidity areas may require more treated lumber to prevent rot and decay.

- Temperature extremes: In colder climates, you may need to use lumber with a lower moisture content to minimize shrinking and warping.

- Insect prevalence: Regions with high termite or carpenter ant populations may necessitate the use of treated or resistant lumber.

Consider these factors when selecting your lumber and calculating your needs.

Structural Considerations

Your home’s structural requirements can also impact your lumber calculations:

- Seismic loads: In earthquake-prone areas, you may need to use additional lumber for bracing and reinforcement.

- Wind loads: High-wind regions may require stronger lumber and closer spacing for framing components.

- Snow loads: Areas with heavy snowfall may necessitate larger roof rafters and beams to support the added weight.

Consult with a structural engineer or experienced contractor to ensure your lumber calculations account for these factors.

Custom Features and Design Elements

Finally, any custom features or unique design elements in your home will affect your lumber requirements:

- Vaulted ceilings: These may require more extended rafters and additional support beams.

- Exposed beams: If you want to showcase your home’s structure, you’ll need to factor in the lumber for these decorative elements.

- Built-in shelving and cabinets: Custom storage solutions will add to your lumber needs.

When planning your lumber calculations, be sure to account for any special features or design elements in your home.

Now that we’ve covered the factors that can impact your lumber requirements, let’s discuss some tips for optimizing your lumber use and keeping costs down.

Tips to Optimize Lumber Use and Lower Costs

Building a new home is a significant investment, and every penny counts. Here are some tips to help you optimize your lumber use and keep your costs under control:

Planning and Ordering Lumber Efficiently

Careful planning and ordering can save you time and money:

- Create a detailed material list: Before ordering, make a comprehensive list of all the lumber you’ll need, including sizes and quantities.

- Order in bulk: Buying lumber in larger quantities can often result in better pricing and fewer trips to the supplier.

- Coordinate with your contractor: Work closely with your builder to ensure your lumber orders align with the construction schedule.

Avoiding Common Mistakes in Lumber Ordering and Cutting

Mistakes can be costly, so be sure to avoid these common pitfalls:

- Double-check your measurements: Always verify your calculations and measurements before ordering or cutting lumber.

- Account for waste: Remember to include a waste factor in your calculations to account for cutting and mistakes.

- Use the right tools: Invest in quality measuring and cutting tools to minimize errors and waste.

You may also read (how much does a house renovation cost on average).